In recent years, more and more companies have been looking for reliable, sustainable, and low-impact solutions to eliminate odors and volatile organic compounds (VOCs) from their production processes. Among the available technologies, air biofiltration has emerged as one of the most effective, especially in contexts that require continuous, safe systems that do not involve the use of chemical substances.

Unlike other filtration methods, based on thermal reactions or adsorbents that need to be replaced periodically, biofiltration relies on a natural principle. For a technical explanation of the biological principle and structure of a biofilter you can consult our article on air biofiltration systems.

In this article, however, we focus on practical aspects: how to achieve high performance, which conditions maximize efficiency, and when this technology represents the ideal choice.

How industrial air biofiltration works

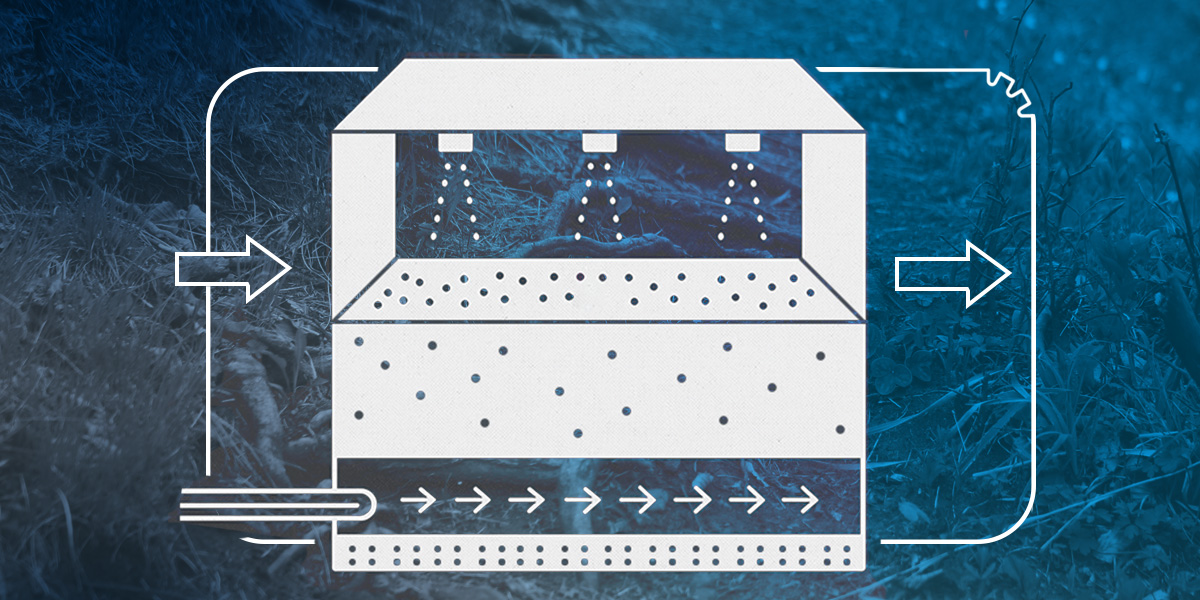

An air biofiltration system conveys polluted airflow inside a biological filter bed, where natural microorganisms break down harmful compounds by transforming them into harmless substances (water, CO₂ and biomass).

The efficiency of the biofiltration process depends on three key variables:

- Humidity, which must remain constant to keep the microbial flora active;

- Temperature, generally between 15 °C and 40 °C;

- Contact time, sufficient to allow uptake and degradation of pollutants.

A proper balance of these parameters enables removal efficiencies of up to 95% for volatile organic compounds and odors.

The benefits of industrial biofilters

In addition to reduced environmental impact, industrial biofilters offer important operational advantages:

- Low operating costs: the system uses natural materials and does not require chemical reagents or frequent replacement of the filter bed.

- Long lifespan of the filtering material: the organic medium naturally settles by around 10% every two years, and can be easily topped up.

- Minimal maintenance: limited to moisture and pH control.

- Operational safety, as the process takes place at room temperature with no risk of explosions or dangerous reactions.

These features make biofiltration particularly competitive with technologies that require more energy consumption.

When to choose industrial biofiltration

Industrial air biofiltration is the ideal solution when:

- pollutants are biodegradable and water-soluble (such as VOCs);

- air flow rates are high but concentrations moderate;

- a continuous and reliable system with low environmental impact is desired;

- the goal is odor neutralization in a natural and safe manner.

They find wide use in waste treatment plants, purifiers, chemical, food industries.

Industrial biofiltration and sustainability

In addition to technical performance, biofiltration contributes to companies' ESG goals, as it reduces emissions and consumption without generating hazardous waste.

It is a circular technology, using natural biological processes to restore balance between production and the environment.

Trust HFiltration's expertise: we design and manufacture tailor-made air biofiltration systems, fully integrable with other purification technologies.

Contact us today to find out how you can improve air quality in your company in a sustainable and regulatory-compliant way.