Preventing explosions in the industrial sector with a safe environment: ATEX HFiltration products

If you want to prevent the risk of explosions inside the industries it is important to put in action the adequate prevention systems to guarantee the safety of the environment. For this reason it is indispensable to install air filtration systems able to abate and eliminate those dusts with explosive properties and make the working area safe.

HFiltration has been working for years in this sector and has developed a series of adequate systems characterized by particularly high safety standards, as well as possessing all the necessary certifications to make them suitable for installation inside ATEX zone 2 and zone 22 areas.

The HF ATEX filtration systems

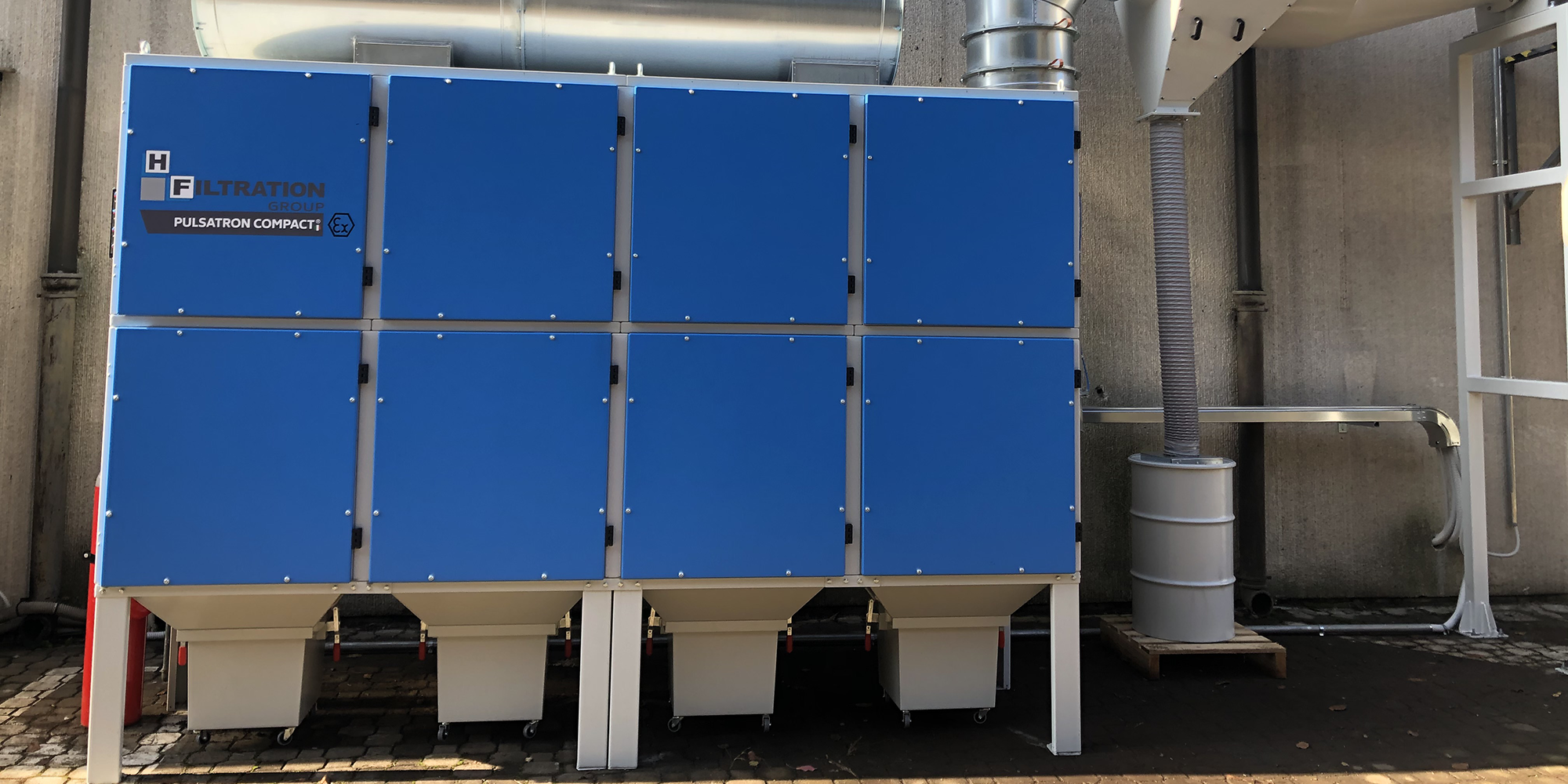

- Pulsatron Compact™ ATEX version, is a modular dust collector with self-cleaning cartridges with high efficiency and ideal for continuous cycle operation. This model is suitable for use in chemical, pharmaceutical, coal, aluminum and zinc processing, powder coating, and food processing industries.

- HJL Cart ATEX version, is a model completely customizable and studied for every single project. Made of S275JR steel it can operate in the presence of medium/high dust loads. This model can be used in companies that perform sandblasting, deburring, welding, grinding, dry machining on machine tools, chemical, epoxy painting, pharmaceutical, plastics, cement and handling of dusty materials.

- Pulsatron H ATEX version, is a modular self-cleaning dust collector of the Pulse-Jet type with pneumatic cleaning of the cartridges by means of a jet of compressed air against the current. Suitable for use in areas where laser and plasma cutting, oxygen cutting operations, food industries, paper industries, contaminated, toxic and hazardous environments are performed.

- HJL Bag ATEX version are customized models designed ad hoc for each customer, suitable for outdoor installation and 24-hour operation cycles. This model can be used in companies that carry out sanding, sandblasting, deburring, combustion of solid and waste materials, drying of solid and assimilable materials, sanding, pneumatic conveying and mixing of dusty materials.

Would you like to know the most suitable type of suction system for your ATEX zone 2 and zone 22 working environment?