Is it possible to have a working area that is free of fumes and dust? How can industrial air be filtered in a simple and optimal way, with guaranteed performance even over the long term? In this article we will try to introduce the topic, illustrating the best techniques to make workplaces healthier and safer.

Fumes and dusts that are created during industrial processes can be particularly harmful to human health, so much so that by law, in the field of occupational safety, it is established how these pollutants must be treated. Furthermore, this problem is common to many production sectors, in particular in the realities involved in the treatment and processing of metals, but also in all those industries where solid materials are handled which, during the different operations, are cut and divided, inevitably producing fumes. and dusts.

The inhalation of these particles is extremely harmful for the health of operators; it can be the cause of numerous pathologies both to the detriment of the respiratory system, primarily the lungs, and in the development of oncological diseases.

In addition to the aspect strictly related to health, the risk of explosions, sometimes triggered by mixtures of fumes and dusts out of control, must not be overlooked.

Plants for the abatement of dusts and fumes:

Workplace safety, regulated by the Law 626/94 and the Consolidated Law on Safety L.D. 81/2008, takes into consideration all those aspects that contribute to ensuring the healthiness of these areas in order to protect workers. Among the requirements deemed necessary there is also the equipment with systems for the abatement of fumes and dust, considered essential to ensure safety in the workplace, particularly in industries where mechanical processing is carried out.

In this panorama there are a series of centralized systems equipped with multiple suction points located in the various areas of the workshop, in particular near the machine tools that emit potentially harmful dust and fumes.

These particular dry filtration systems, although different from each other, all have the same three phases:

- Removal of smoke and dust from the polluting source thanks to a ducting system and a special extractor

- Air filtration

- Expulsion of clean and purified air.

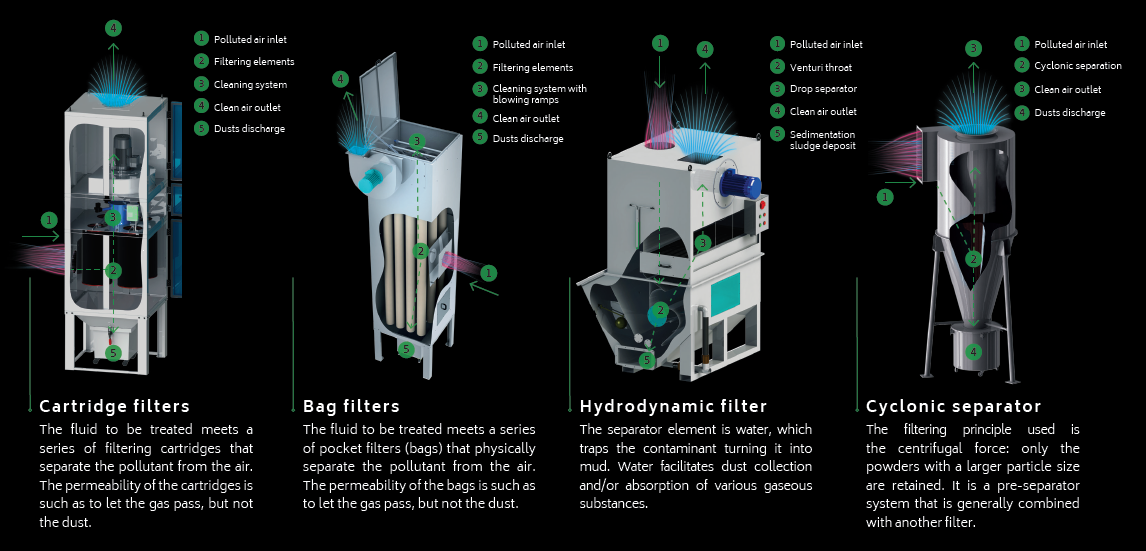

Example of HFiltration's technologies to abate fumes and dust.

Each dry suction system intended for the abatement of industrial dust and fumes must be studied according to the individual needs of the company, taking into account the type of pollutant to be treated, the volume produced and the organization of the working area.

Furthermore, the choice of the suitable plant for the abatement of dust and fumes will have positive implications also on the organizational level, thanks to the cleaner environment and the consequent reduction of the time to be dedicated to the removal of dust from the surfaces, but also economic as if recovered, the latter can be returned to the production cycle.