In this article, we will examine the main risks associated with exposure to cooling lubricants, pollutants often underestimated despite their potential to cause serious harm.

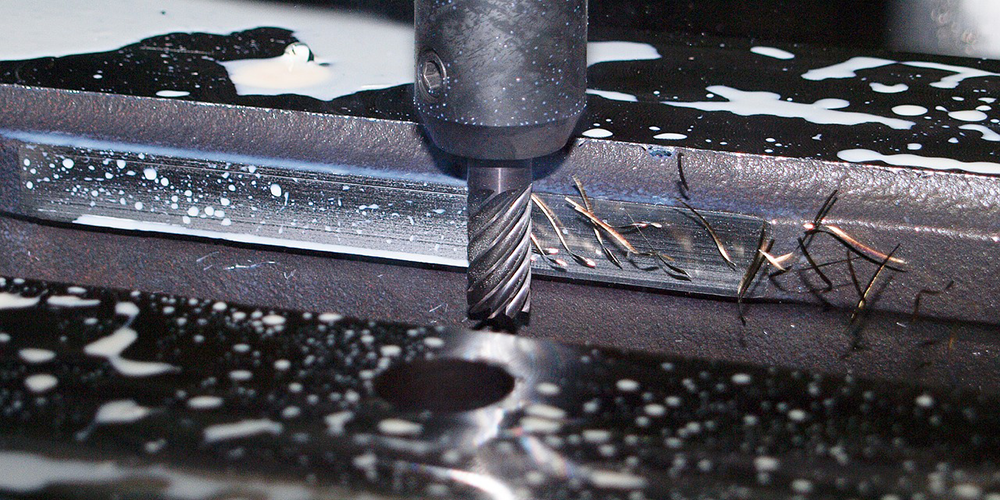

Cooling lubricants are all those liquids used to lubricate cutting tools, serving to cool and wash away the chips produced during machining, thereby reducing friction and wear. These substances are usually lubricating oils of mineral, vegetable, or synthetic origin, and in some cases, they are water-miscible.

There are multiple emulsions with different formulations, to be used depending on the material being processed and the tool employed. Typically, these solutions consist of about 50% lubricating oil, combined with specific additives and water.

The European REACH regulation provides guidance on the selection of cooling lubricants and maintains a semi-annual list of the most hazardous substances through the ECHA. Substances to avoid include those containing boron and formaldehyde donors, which are considered particularly harmful.

The disposal of spent cooling lubricants must also follow specific procedures, as they are classified as industrial waste. They must be coded according to the CER system and collected by authorized companies. Regulations also distinguish between mineral oils, synthetic oils, emulsions, and solutions, as well as between halogenated and non-halogenated products.

What does exposure to cooling lubricants mean for health?

According to Legislative Decree 81/2008, the presence of cooling lubricants must be indicated in the company’s risk assessment, as these substances pose a real hazard to workers’ health.

But what are the main harms associated with exposure to these pollutants?

-

The lipid-solubilizing action of emulsifiers and the alkaline component can significantly damage the skin’s protective barrier.

-

The decomposition of certain additives can produce degreasing, irritating, and sensitizing substances that may cause harm.

-

The use of substances such as pyrithione, thiazoles, isothiazolinones, phenolic derivatives, formaldehyde, and biocides has been shown to cause irritation, sensitization, and percutaneous toxicity.

In this context, it is clear that prolonged exposure to cooling lubricants can lead to dermatitis, allergies, respiratory disorders, and, in the worst cases, carcinogenic effects.

To reduce the risks associated with cooling lubricants, it is essential to implement targeted solutions for filtering and purifying industrial air, thus ensuring a safer and healthier work environment.

Do you want to know if your company and its employees are exposed to industrial pollutants? Contact us today!